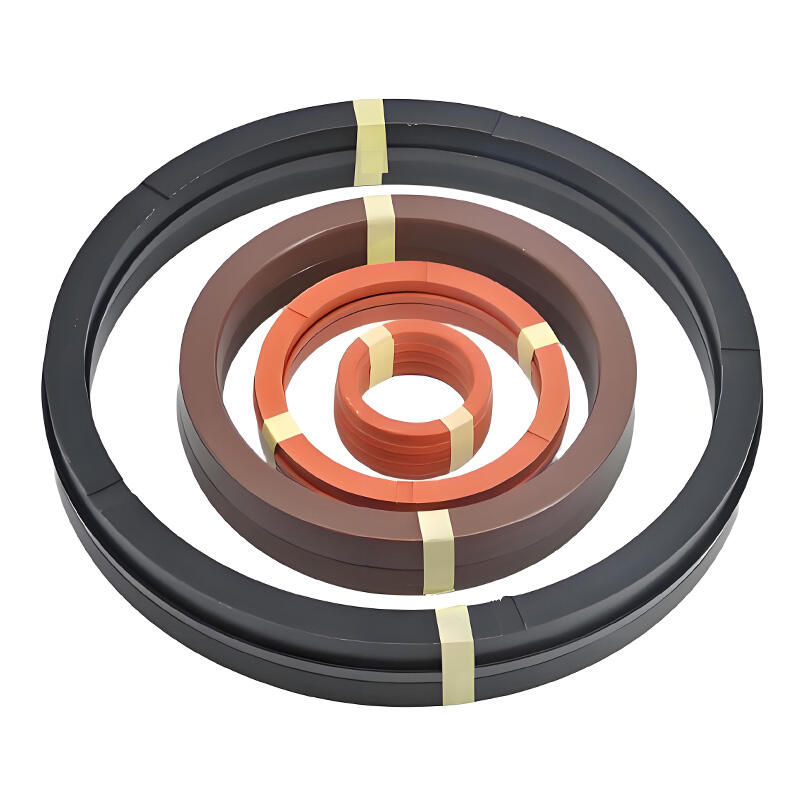

automotive o rings

Automotive O rings are essential sealing components designed to prevent leakage in various automotive systems. These precision-engineered circular gaskets, typically made from elastomeric materials like nitrile rubber, silicone, or fluorocarbon, create reliable seals between two or more parts in vehicles. They function by filling the gap between mating surfaces, maintaining their integrity under varying pressures and temperatures. These versatile components are crucial in engine systems, transmission assemblies, fuel systems, and hydraulic applications. The rings feature specific design characteristics, including precise cross-sectional diameters and material compositions, ensuring optimal performance across different automotive applications. Their ability to maintain seal integrity under dynamic conditions, including extreme temperatures ranging from -40°F to 400°F, makes them indispensable in modern vehicles. Advanced manufacturing processes ensure consistent quality and precise specifications, while material innovations have led to enhanced durability and chemical resistance. These components play a vital role in maintaining system efficiency, preventing fluid leaks, and ensuring proper operation of critical vehicle systems.