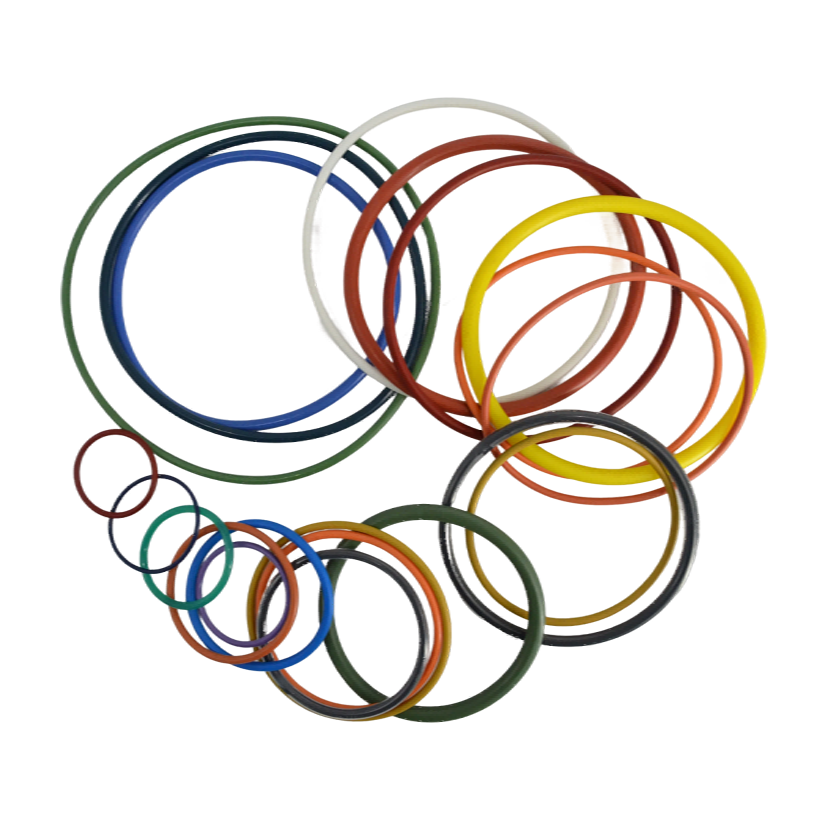

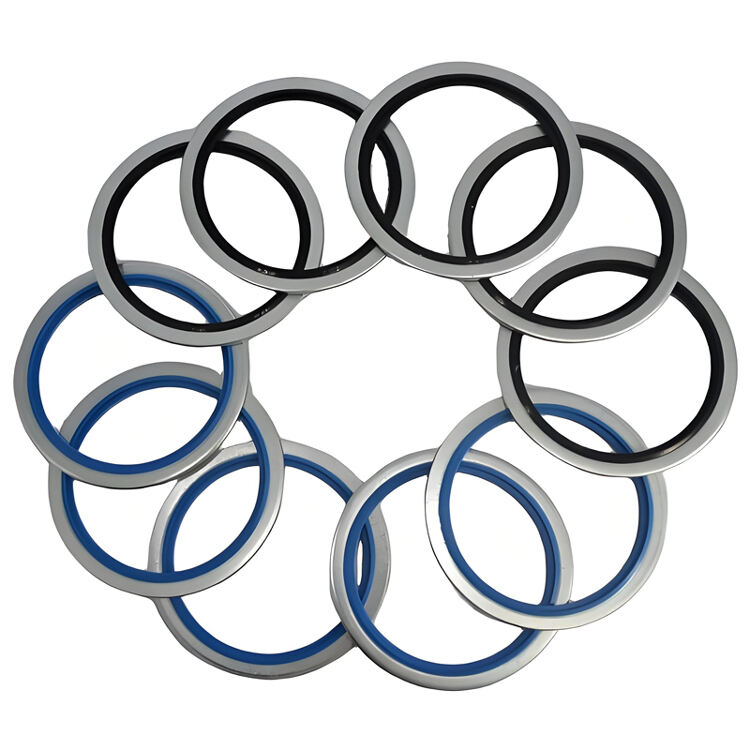

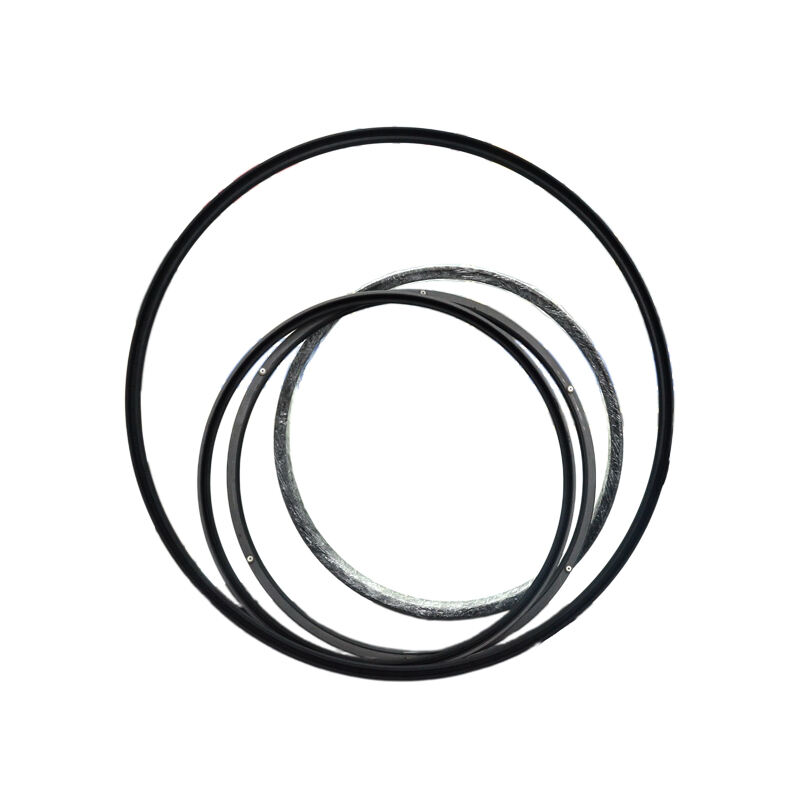

O Rings

O Rings are common and essential sealing components widely used in various industries, including machinery, automotive, aerospace, chemicals, and medical fields.

- Overview

- Related Products

O Rings are common and essential sealing components widely used in various industries, including machinery, automotive, aerospace, chemicals, and medical fields. Though their design is simple—taking the shape of a ring—they play a crucial role in sealing during operation.

O-Rings are made from a variety of elastomeric materials to suit different working environments and chemical exposures. Some common materials include:

Nitrile Rubber (NBR): Known for its excellent oil resistance, nitrile rubber is ideal for environments with mineral oils, lubricants, and non-polar solvents. It also offers good abrasion resistance and aging resistance, though its performance may be limited in extremely high or low-temperature environments.

Fluoroelastomer (FKM, also known as Viton): This material provides outstanding heat resistance and chemical stability, making it resistant to high temperatures, oils, fuels, and various chemicals. It is well-suited for harsh working conditions.

Silicone Rubber: Silicone rubber excels in both high and low-temperature resistance, making it suitable for use in a broad temperature range. It is commonly found in food processing and medical applications and also offers good electrical insulation properties.

Ethylene Propylene Diene Monomer (EPDM): This material is popular in brake systems and coolant environments due to its excellent heat resistance, ozone resistance, and aging resistance. However, it should not be used in petroleum-based Products.

Characteristics and Applications

O-Rings are widely used due to their unique characteristics:

Simple and Effective Design: With a straightforward shape, O-Rings can provide efficient sealing in axial, radial, static, and dynamic applications. Their design and installation are relatively simple, helping to reduce costs.

Versatility: The variety of materials used in O-Rings allows them to handle almost any fluid or environment, from the extreme heat of an engine to the cold vacuum of outer space.

Durability: When used in the appropriate environment, O-Rings can endure millions of pressurized cycles without failure, offering long-lasting performance.

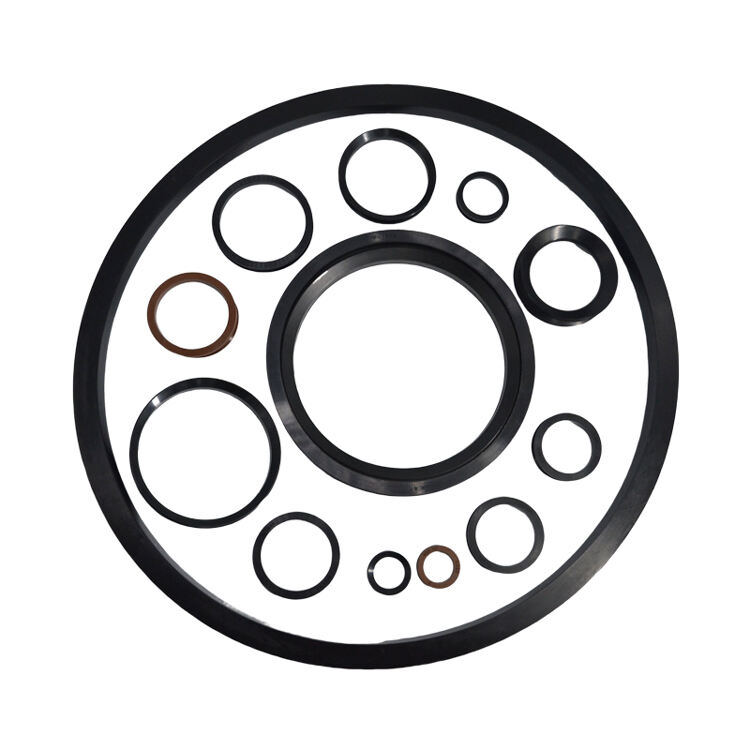

These factors collectively make O-Rings a critical component in numerous industries, providing both reliability and cost savings.

Please refer to our sizing charts for dimensions.