- Overview

- Related Products

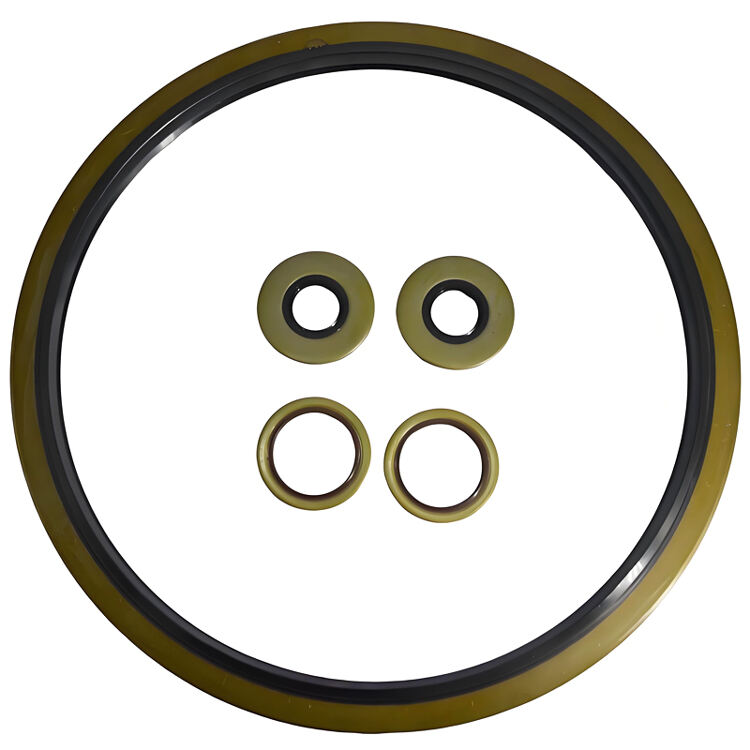

KC Oil Seal

Similar to the TC oil seal, the KC oil seal also adopts a double-lip design, but it features enhanced sealing capabilities through modifications tailored to specific equipment. Like the TC seals, KC oil seals are often made from nitrile rubber or fluororubber, providing excellent sealing performance, flexibility, and resistance to wear. These seals are commonly used in hydraulic systems, transmissions, and heavy machinery, where a reliable seal is crucial for maintaining system integrity under fluctuating pressure and temperature conditions.

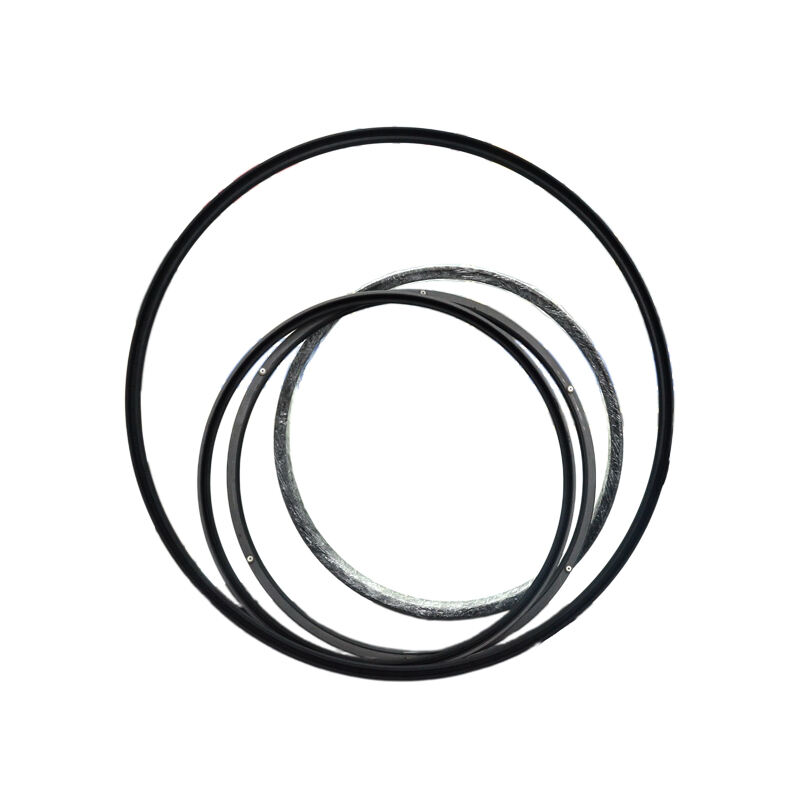

VC Oil Seal

VC oil seal is typically a single-lip design, often made from materials such as fluororubber or silicone rubber. This type of seal is particularly effective for low-speed applications and provides basic sealing functions. The VC seal is designed to operate under conditions with low friction and moderate to low pressure, making it suitable for general rotating shaft applications. It is widely used in equipment where a simple sealing solution is sufficient, such as small motors or pumps.

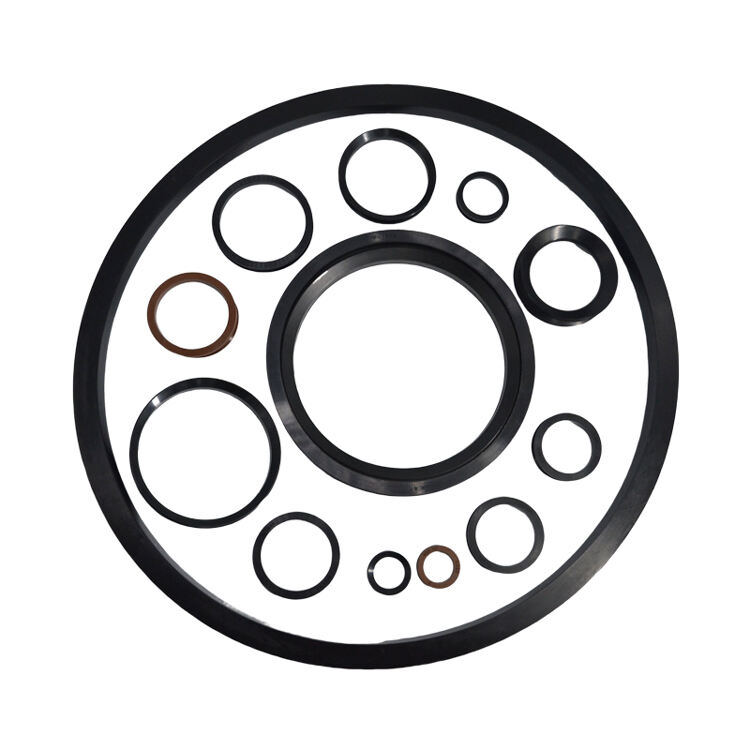

TA Oil Seal

TA oil seal is designed with a reinforced structure, which gives it added strength and durability to handle high pressure and temperature environments. These seals are made from a variety of elastomer materials that are specifically chosen for their resistance to extreme conditions. TA oil seals are often used in specialized industrial applications where high-performance sealing is required, such as in chemical processing equipment, hydraulic machinery, and high-pressure systems. They are designed to maintain effective sealing even under challenging operating conditions.

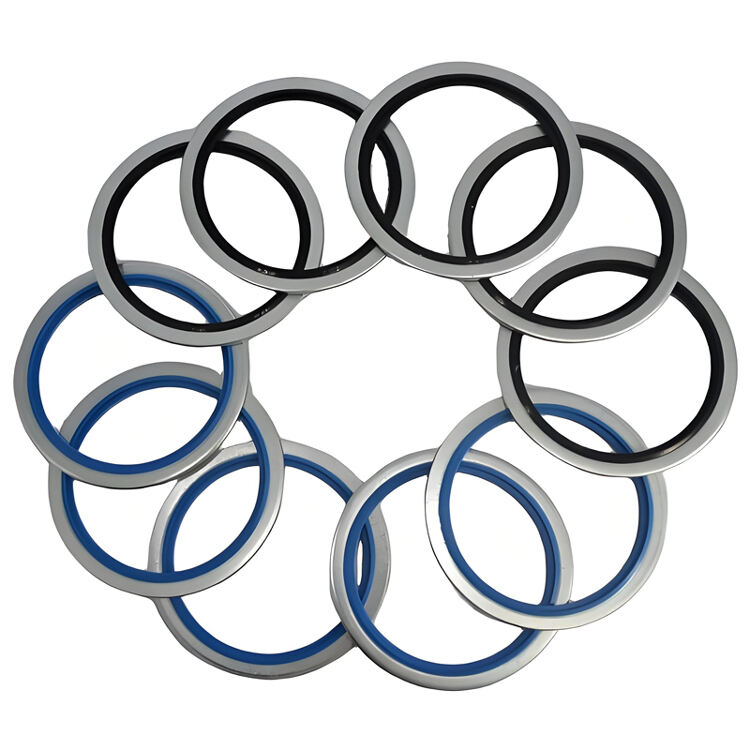

TB Oil Seal

TB oil seal is another double-lip design that is specifically engineered for high-pressure and heavy-load applications. Made from high-temperature-resistant materials, the TB seal offers superior sealing performance, ensuring a tight seal in demanding environments. This oil seal type is ideal for use in heavy machinery, such as construction equipment and industrial systems that operate under high mechanical loads or extreme temperatures. The TB oil seal is known for its durability and resilience in challenging industrial environments.