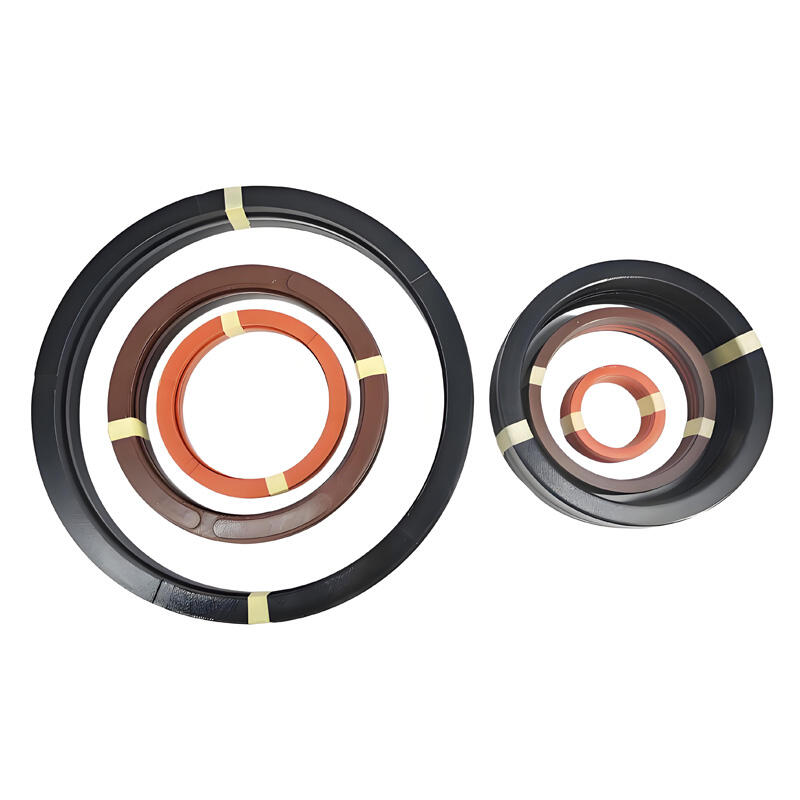

oil seal tcn

The oil seal TCN represents a significant advancement in sealing technology, designed specifically for demanding industrial applications where reliable fluid containment is crucial. This specialized seal combines traditional nitrile rubber with advanced TCN (Terpolymer of Ethylene, Acrylic Ester, and Carbonmonoxide) material technology, resulting in exceptional resistance to heat, chemical exposure, and mechanical stress. The seal features a precision-engineered lip design that maintains consistent contact pressure against the shaft, ensuring optimal sealing performance even under challenging operating conditions. With its robust construction, the oil seal TCN can effectively prevent oil leakage while simultaneously keeping contaminants out of the system. The seal's innovative design incorporates reinforced side walls that enhance structural stability and prevent deformation under high-pressure conditions. Additionally, the TCN material composition provides superior aging resistance, maintaining its physical properties and sealing effectiveness over extended periods. This makes it particularly suitable for applications in automotive transmissions, heavy machinery, industrial gearboxes, and various manufacturing equipment where reliable sealing is essential for operational continuity and maintenance reduction.