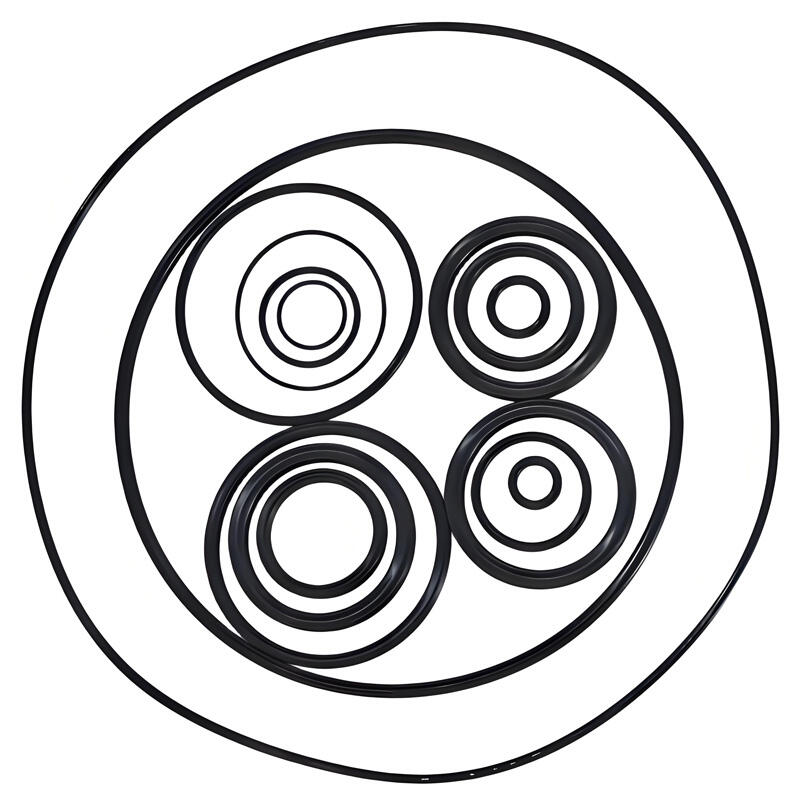

agricultural machine oil seal

Agricultural machine oil seals are critical components designed to prevent oil leakage and protect machinery from contamination in farming equipment. These precision-engineered seals create an effective barrier between moving parts, maintaining optimal lubrication while keeping dirt, dust, and moisture out of sensitive mechanical systems. Made from high-grade materials like nitrile rubber, polyacrylate, or fluoroelastomers, these seals are specifically engineered to withstand the harsh conditions common in agricultural operations. They feature a robust design with a spring-loaded sealing lip that maintains consistent contact pressure against the shaft, ensuring reliable sealing performance even under varying temperatures and pressures. The seals are manufactured to precise specifications, accommodating different shaft sizes and operating conditions typical in agricultural machinery such as tractors, harvesters, and irrigation systems. With advanced surface treatment technologies and specialized coating applications, these seals offer enhanced wear resistance and extended service life, contributing to reduced maintenance requirements and improved equipment reliability.