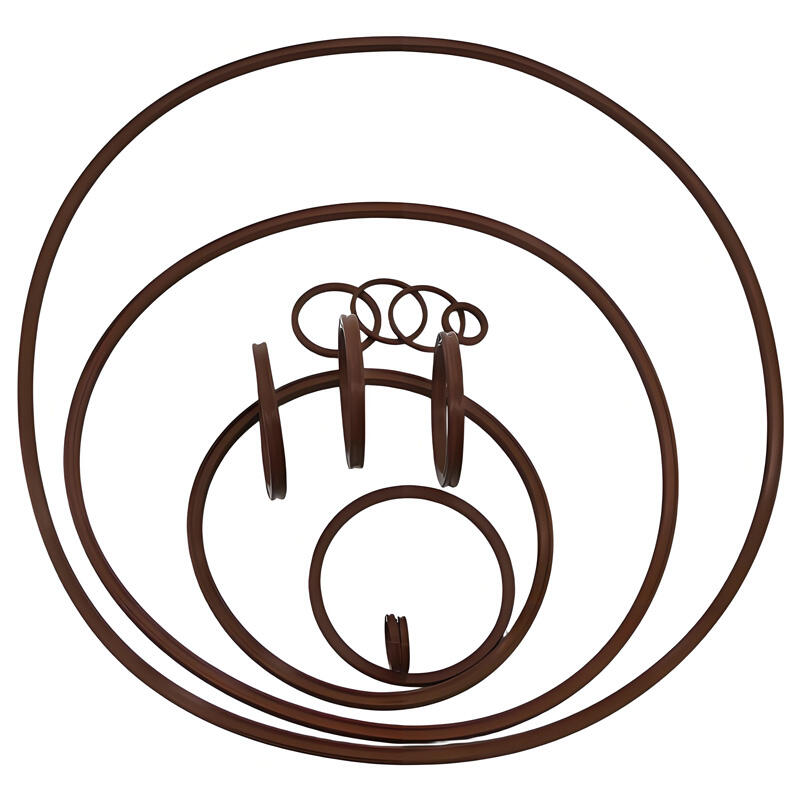

high temperature o ring seals

High temperature O-ring seals represent a critical component in industrial applications where extreme heat resistance is paramount. These specialized sealing solutions are engineered to maintain their integrity and performance in environments where temperatures can exceed 500°F (260°C). Constructed from advanced materials such as fluoroelastomer (FKM), perfluoroelastomer (FFKM), or silicone rubber, these O-rings effectively prevent leakage of fluids and gases while withstanding severe thermal conditions. The unique molecular structure of these materials enables them to resist degradation, maintain flexibility, and prevent hardening or cracking under prolonged exposure to high temperatures. These seals find extensive use in automotive engines, aerospace applications, chemical processing equipment, and power generation systems. Their design incorporates specific groove dimensions and compression ratios that account for thermal expansion, ensuring consistent sealing performance even as temperatures fluctuate. The manufacturing process involves precise quality control measures to guarantee uniform material distribution and dimensional accuracy, which are essential for reliable sealing in high-temperature applications.