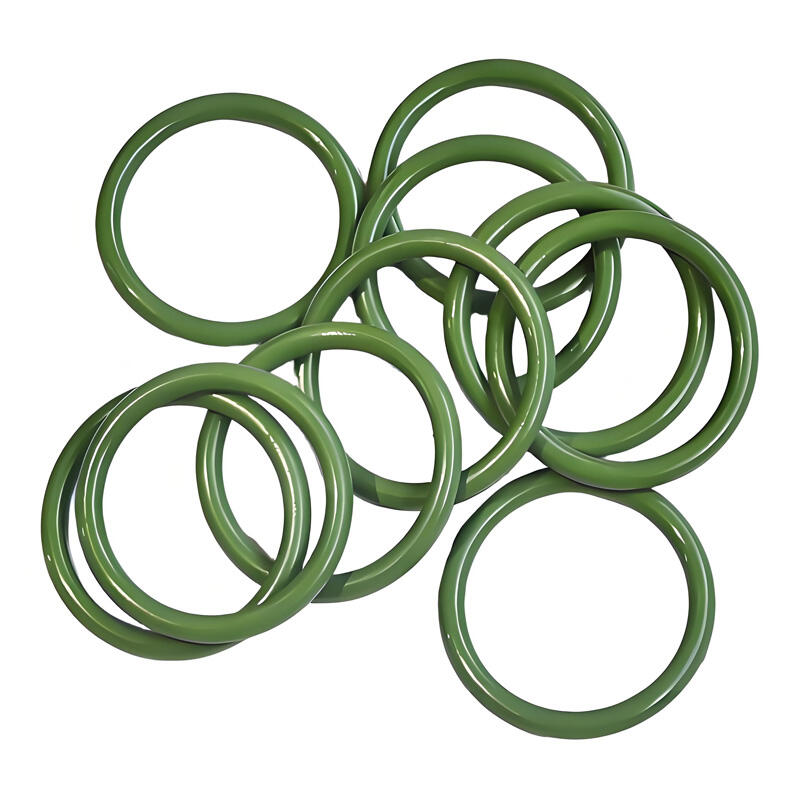

o ring seal viton

O ring seal viton, a high performance fluoroelastomer, represents a critical component in modern sealing solutions. This synthetic rubber material, developed specifically for demanding industrial applications, offers exceptional resistance to chemicals, oils, and extreme temperatures ranging from -15°F to 400°F. The viton o ring seal's molecular structure provides outstanding compression set resistance and maintains its sealing properties even under severe operating conditions. These seals are engineered with precise dimensions and cross sections to ensure optimal sealing performance in dynamic and static applications. The material's unique composition allows it to withstand aggressive fluids, including petroleum based oils, synthetic hydraulic fluids, and many organic solvents that would deteriorate conventional rubber seals. In industrial settings, these seals are extensively used in automotive, aerospace, chemical processing, and oil and gas industries, where reliability and longevity are paramount. Their superior heat resistance makes them ideal for high temperature applications, while their excellent chemical compatibility ensures extended service life in corrosive environments.