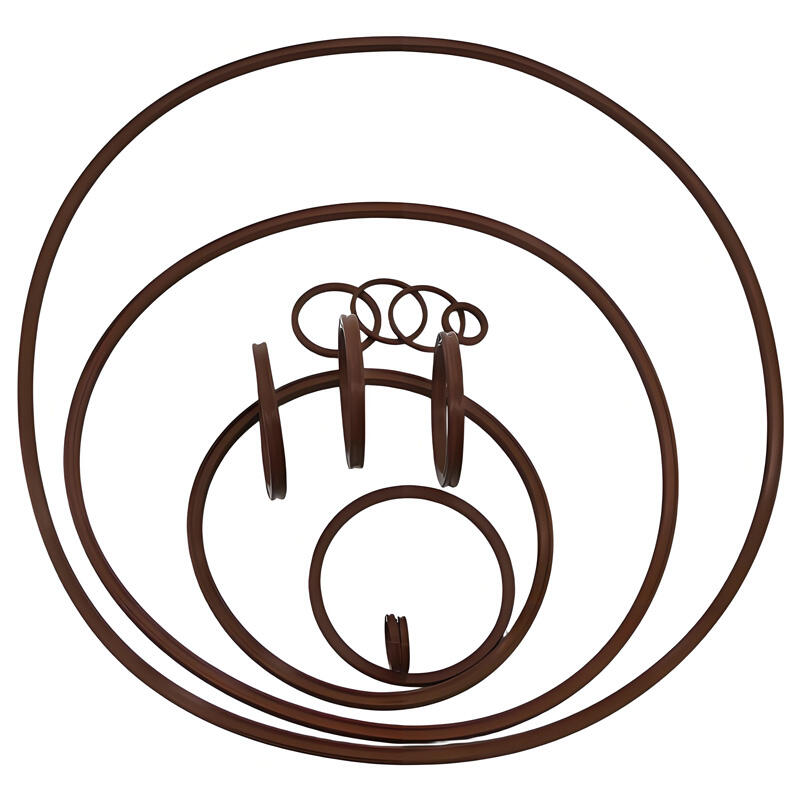

o ring seal manufacturers

O ring seal manufacturers are specialized industrial enterprises dedicated to producing high-quality sealing solutions essential for various mechanical and fluid systems. These manufacturers employ advanced manufacturing processes and quality control measures to create precision-engineered O rings that prevent leakage and maintain system integrity. Using state-of-the-art machinery and materials, they produce O rings in diverse sizes, materials, and specifications to meet different industry requirements. Their production capabilities typically include rubber compounds, silicone, PTFE, and other elastomeric materials, ensuring compatibility with various operating environments and media. These manufacturers maintain strict adherence to international standards such as ISO 9001 and specific industry certifications, guaranteeing consistent product quality and reliability. Their facilities are equipped with advanced testing laboratories for material analysis, compression testing, and durability assessment. Modern manufacturing processes incorporate automation and precision molding techniques, ensuring dimensional accuracy and surface finish quality. These manufacturers also provide custom solutions, working closely with clients to develop specialized O rings for unique applications in aerospace, automotive, medical, and industrial sectors.