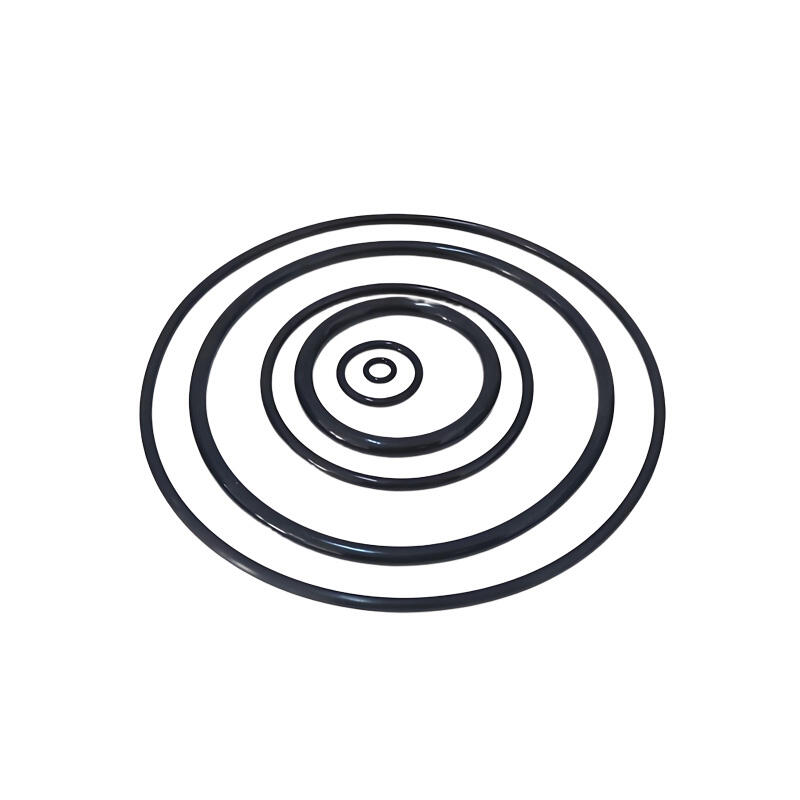

car oil seal

A car oil seal is a crucial component in automotive engineering, designed to prevent oil leakage and maintain proper lubrication within various vehicle systems. This precision-engineered part creates an effective barrier between moving and stationary components, ensuring that lubricants remain contained while keeping harmful contaminants out. Made from high-grade materials such as nitrile rubber, polyacrylate, or silicone, these seals are engineered to withstand extreme temperatures, pressure variations, and chemical exposure. The design typically features a spring-loaded sealing lip that maintains constant contact with the shaft surface, providing reliable sealing performance throughout the vehicle's operational life. Car oil seals are strategically placed in critical areas such as the crankshaft, camshaft, wheel bearings, and transmission systems, where they play a vital role in maintaining engine efficiency and preventing mechanical wear. Their sophisticated design incorporates multiple sealing lips and protective features that ensure optimal performance under various driving conditions, from everyday commuting to high-performance applications. The advancement in seal technology has led to enhanced durability and improved resistance to aging, making modern car oil seals more reliable and longer-lasting than ever before.