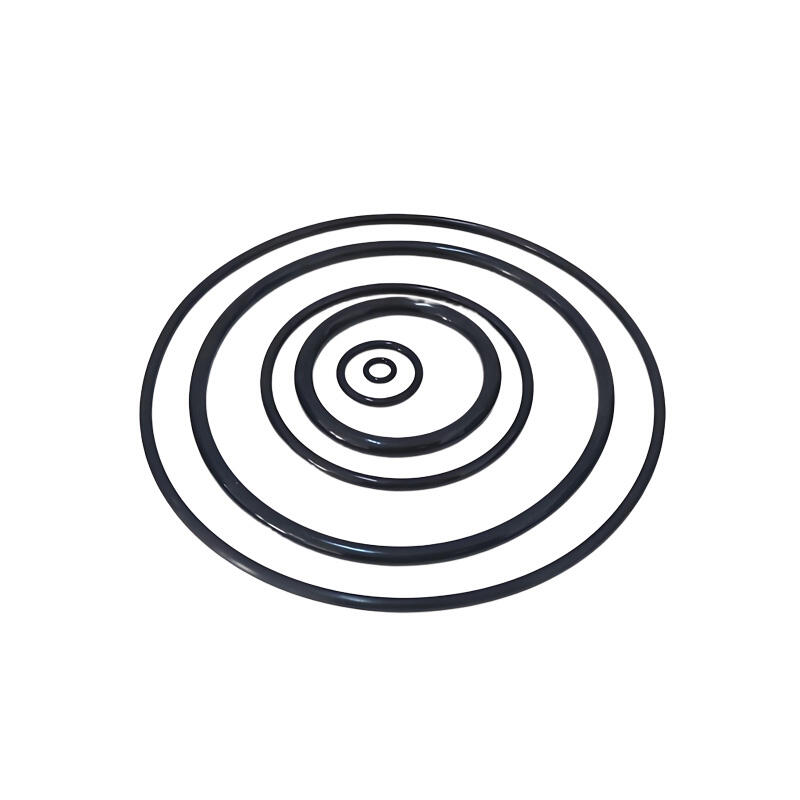

small o rings

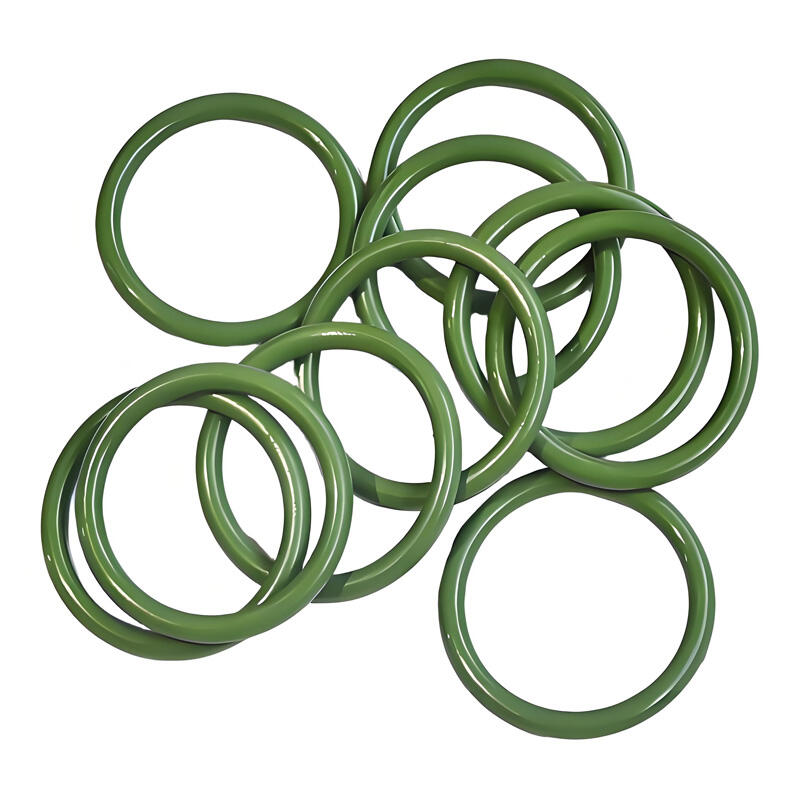

Small O rings are essential sealing components widely used in various industries and applications. These circular, elastomeric seals are designed to prevent leakage of fluids and gases between two mating surfaces. Typically manufactured from materials like nitrile rubber, silicone, or EPDM, small O rings create a reliable seal when compressed between two surfaces. Their simple yet effective design consists of a doughnut-shaped cross-section that deforms under pressure to fill gaps and maintain a tight seal. These versatile components come in various sizes, with inner diameters ranging from fractions of a millimeter to several centimeters, making them suitable for numerous applications. The durability and reliability of small O rings make them indispensable in hydraulic systems, pneumatic equipment, automotive applications, and various industrial machinery. Their ability to withstand different temperatures, pressures, and chemical environments, coupled with their cost-effectiveness and ease of installation, has made them a fundamental component in modern engineering and manufacturing processes.