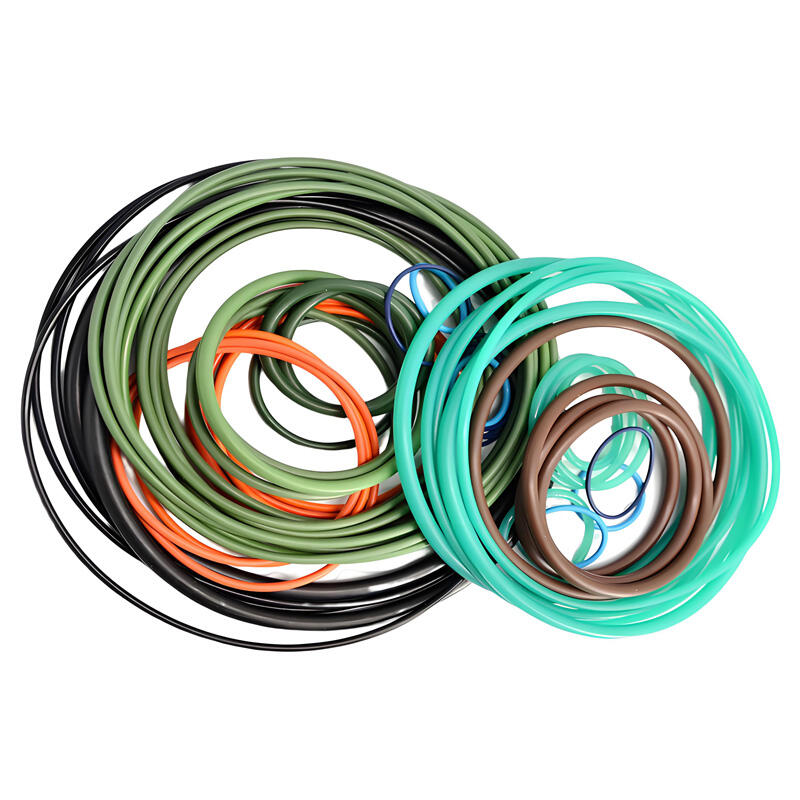

viton seal ring

A Viton seal ring represents a critical component in various industrial applications, engineered from high-performance fluoroelastomer material. These specialized sealing solutions offer exceptional resistance to chemicals, oils, and extreme temperatures, making them indispensable in demanding environments. The seal rings feature a unique molecular structure that provides outstanding compression set resistance and maintains integrity even under harsh operating conditions. Primarily utilized in industrial machinery, automotive systems, and chemical processing equipment, Viton seal rings effectively prevent leakage and contamination while ensuring system efficiency. Their temperature tolerance ranges from -20°F to 400°F (-29°C to 204°C), offering remarkable versatility across different applications. The material's inherent properties allow these seals to resist degradation from exposure to fuels, oils, and aggressive chemicals, contributing to extended service life and reduced maintenance requirements. Their precise engineering ensures consistent performance in both static and dynamic sealing applications, while their excellent shape retention properties maintain sealing effectiveness over extended periods.