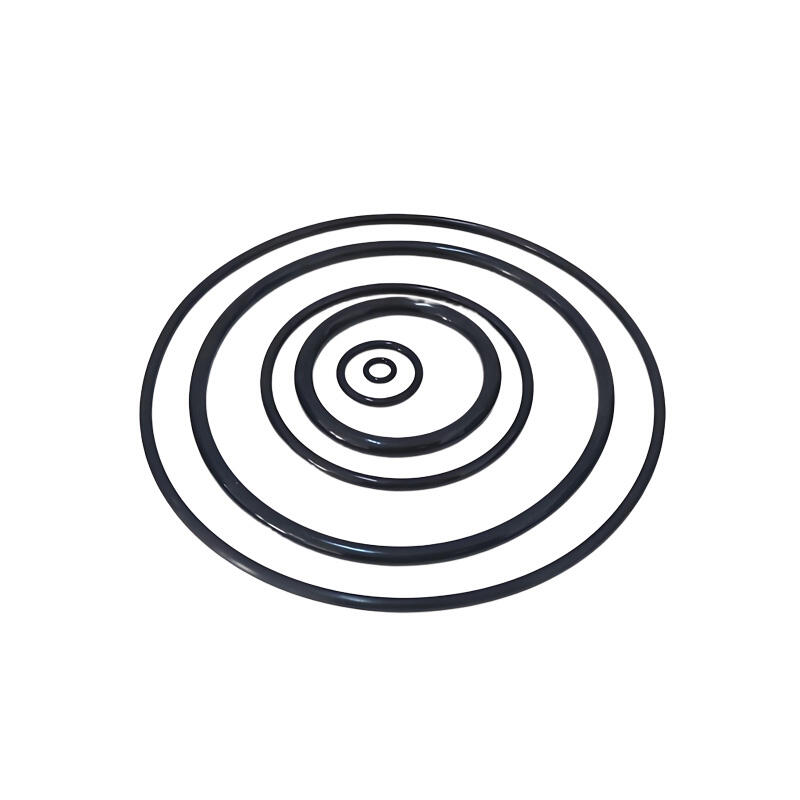

national oil seal

A national oil seal represents a critical mechanical component designed to prevent fluid leakage and contamination in various industrial applications. These precision-engineered seals consist of high-quality elastomeric materials combined with reinforcing metal or fabric elements, creating a robust barrier against oil, grease, and other fluids. The primary function involves maintaining a reliable seal between rotating and stationary components in machinery, effectively containing lubricants while preventing external contaminants from entering the system. National oil seals incorporate advanced lip design technology, featuring precisely engineered contact surfaces that maintain optimal pressure distribution during operation. The seals demonstrate exceptional durability across diverse operating conditions, including extreme temperatures and high-speed applications. Their versatile design accommodates both inch and metric sizing standards, making them suitable for a wide range of industrial equipment, automotive applications, and heavy machinery. The manufacturing process involves stringent quality control measures, ensuring consistent performance and extended service life. These seals also feature specialized surface treatments that enhance wear resistance and reduce friction, contributing to improved energy efficiency and reduced maintenance requirements.