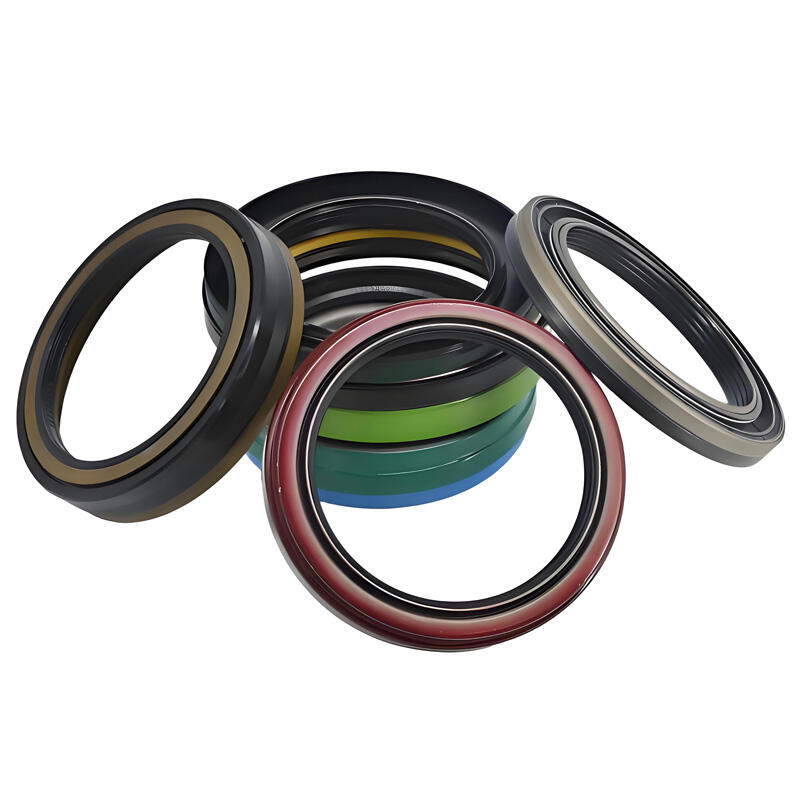

tc seals

TC seals represent a significant advancement in industrial sealing technology, offering superior performance in demanding applications. These specialized seals are engineered with a unique combination of materials, typically featuring a PTFE sealing lip supported by an elastomeric energizing element. This design enables TC seals to withstand extreme temperatures ranging from -70°C to +260°C while maintaining their structural integrity and sealing capabilities. The seals excel in both rotary and reciprocating applications, providing exceptional chemical resistance and low friction characteristics. They are particularly valued in industries where contamination control is crucial, such as food processing, pharmaceutical manufacturing, and chemical processing. The seals feature a precision-engineered design that prevents media ingress while retaining lubricants effectively. Their robust construction includes reinforced lips that resist wear and deformation, ensuring extended service life even under challenging operating conditions. TC seals are available in various configurations to accommodate different shaft sizes and installation requirements, making them versatile solutions for diverse industrial applications. Their self-lubricating properties and minimal stick-slip behavior contribute to smooth operation and reduced maintenance requirements.