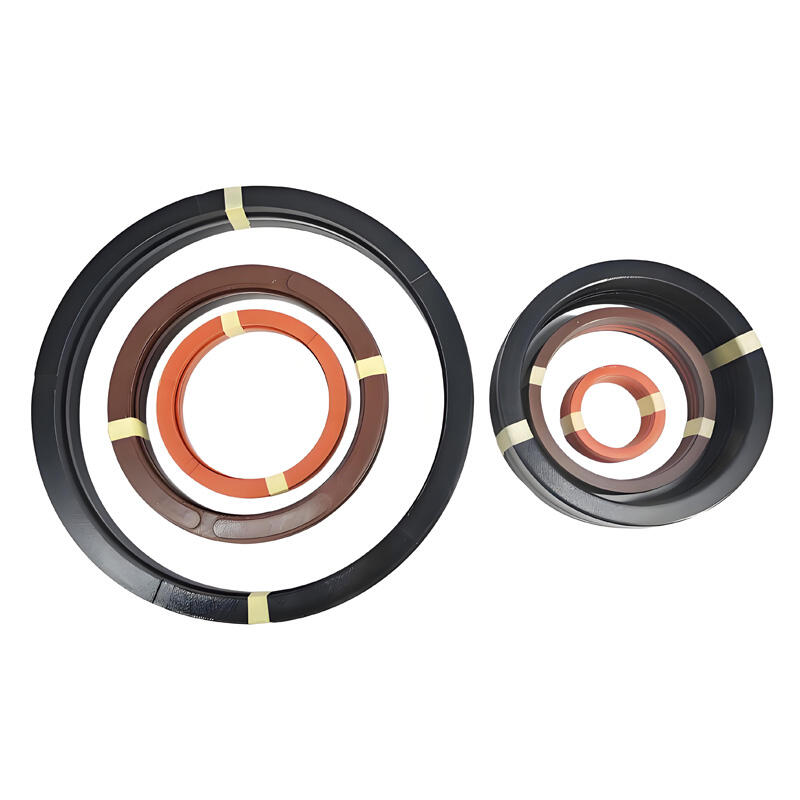

hydraulic cylinder oil seal

A hydraulic cylinder oil seal is a critical component designed to prevent oil leakage and maintain system pressure in hydraulic systems. These specialized seals are engineered to withstand high pressure conditions while ensuring optimal performance of hydraulic cylinders. The primary function involves creating an impermeable barrier between moving parts, effectively containing hydraulic fluid within the system while preventing external contaminants from entering. Modern hydraulic cylinder oil seals are manufactured using advanced materials such as nitrile rubber, polyurethane, or PTFE, each offering specific advantages in terms of temperature resistance, chemical compatibility, and durability. These seals are precisely engineered to maintain their integrity under various operating conditions, including extreme temperatures and high pressure scenarios. The design typically incorporates multiple sealing lips and reinforced structures to ensure reliable performance and extended service life. In industrial applications, these seals are essential components in construction equipment, manufacturing machinery, aerospace systems, and marine applications. The technology behind hydraulic cylinder oil seals continues to evolve, with manufacturers developing innovative solutions to meet increasingly demanding operational requirements while maintaining cost effectiveness.