auto oil seal

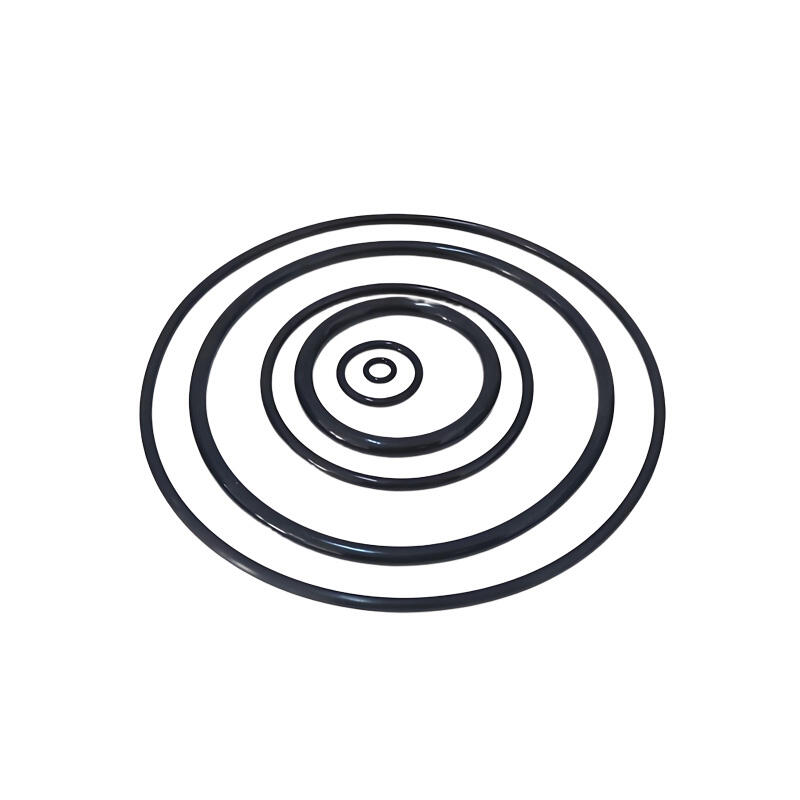

Auto oil seals are critical components in vehicular systems, designed to prevent oil leakage and maintain proper lubrication within mechanical assemblies. These precision-engineered devices create an effective barrier between moving and stationary parts, ensuring optimal performance and longevity of automotive systems. The primary function of an auto oil seal is to retain lubricants within the machinery while simultaneously preventing external contaminants from entering the system. Modern auto oil seals incorporate advanced materials such as nitrile rubber, silicone, and fluorocarbon elastomers, enabling them to withstand extreme temperatures, chemical exposure, and high-speed rotation. The design typically features a flexible lip that maintains constant contact with the shaft surface, creating a dynamic seal that adjusts to operational conditions. These seals are utilized in various automotive applications, including transmission systems, wheel bearings, crankshafts, and differential assemblies. The technology behind auto oil seals continues to evolve, with manufacturers implementing innovative features like double-lip designs for enhanced sealing capability and specialized surface treatments for reduced friction and increased durability.