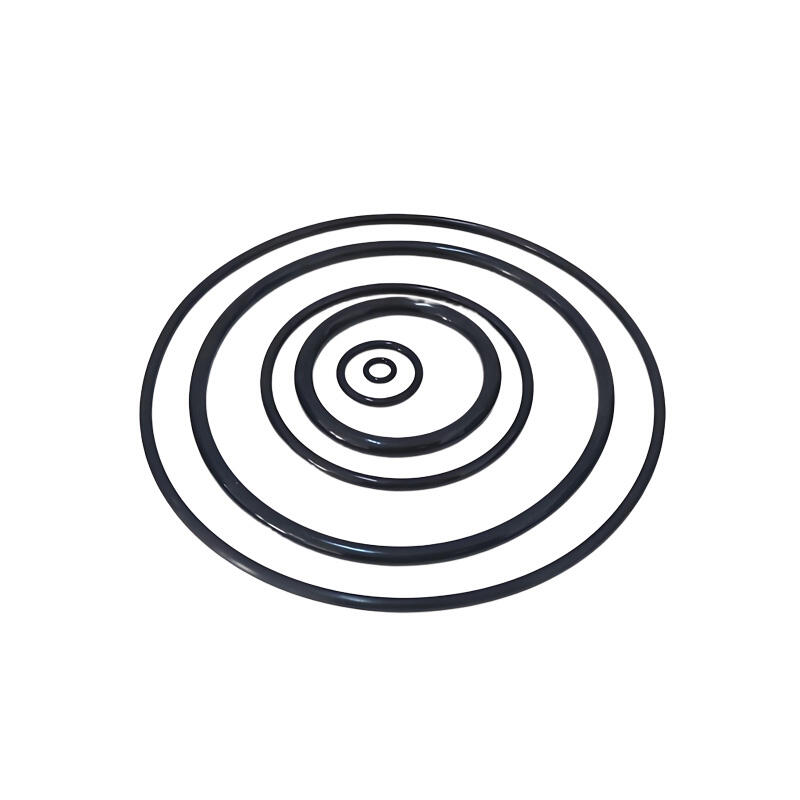

high pressure o rings

High pressure O rings are essential sealing components designed to maintain integrity under extreme pressure conditions. These precision-engineered elastomeric rings create reliable seals between two or more parts in mechanical assemblies, preventing leakage of fluids or gases. Manufactured from high-grade materials such as fluorocarbon, EPDM, or silicone, these O rings maintain their structural integrity and sealing properties even when subjected to pressures exceeding 3000 PSI. The unique design features a circular cross-section that, when compressed, creates an effective barrier against both internal and external pressures. Their versatility allows for implementation in various industrial applications, from hydraulic systems and pneumatic equipment to high-pressure valves and compressors. The rings undergo rigorous testing to ensure compliance with industry standards and maintain consistent performance across temperature ranges from -40°F to 400°F. Modern manufacturing processes ensure precise dimensional accuracy and surface finish, critical factors in achieving optimal sealing performance. These O rings are also designed with specific groove dimensions and squeeze ratios to maximize their sealing effectiveness while preventing excessive deformation under high-pressure conditions.