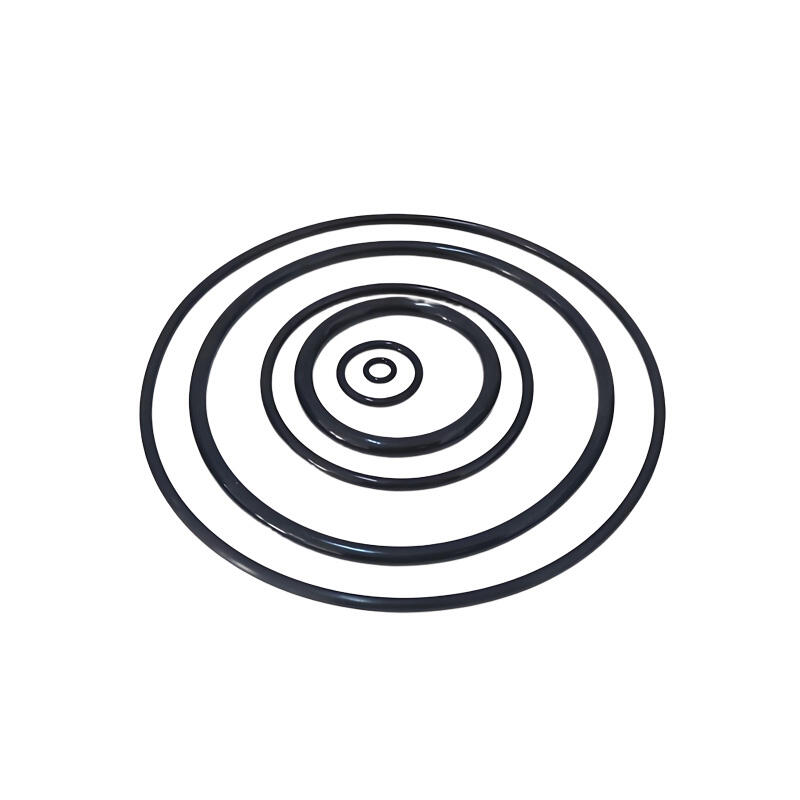

rubber o ring seals

Rubber O ring seals are essential components in modern engineering and manufacturing, serving as critical elements in maintaining leak proof connections between two or more parts. These circular elastic seals, made from various elastomeric materials, create an effective barrier against liquids and gases when compressed between mating surfaces. The unique design of O rings features a round cross section that, when properly installed, deforms to fill the cavity and creates a reliable seal under pressure. These seals function through a combination of initial squeeze and pressure activation, where system pressure actually enhances the sealing effect. O rings are widely utilized across numerous industries, from automotive and aerospace to medical devices and consumer electronics. Their versatility allows them to operate effectively across a broad temperature range, from -65°F to 400°F, depending on the material selection. Modern manufacturing techniques ensure precise dimensional control, with tolerances often held to within .001 inch, guaranteeing consistent performance. The seals can be manufactured in sizes ranging from microscopic to several feet in diameter, accommodating virtually any application requirement. Their simple yet effective design makes them one of the most cost efficient and reliable sealing solutions available today.