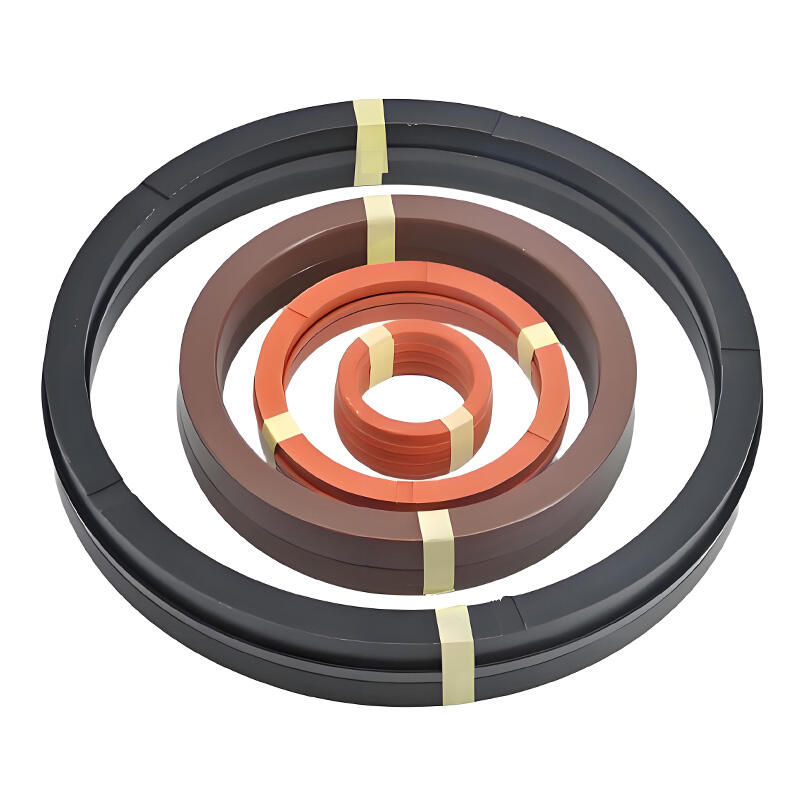

o ring seal price

O ring seal pricing represents a crucial consideration in industrial and manufacturing contexts, encompassing various factors that influence the final cost of these essential sealing components. The price structure typically reflects the material composition, size specifications, quantity ordered, and specialized requirements for specific applications. High-performance materials like fluorocarbon (FKM) and silicone generally command higher prices compared to standard nitrile (NBR) options, while custom sizes or specialized coatings can further impact costs. Manufacturers often offer volume discounts, making bulk purchases more economical for large-scale operations. The pricing also factors in industry certifications, quality standards, and testing requirements, particularly for applications in aerospace, medical, or food-grade environments. Additionally, market dynamics, raw material availability, and global supply chain conditions can influence pricing fluctuations. Understanding these pricing components helps businesses make informed decisions when selecting o ring seals for their specific applications while maintaining cost-effectiveness and performance requirements.