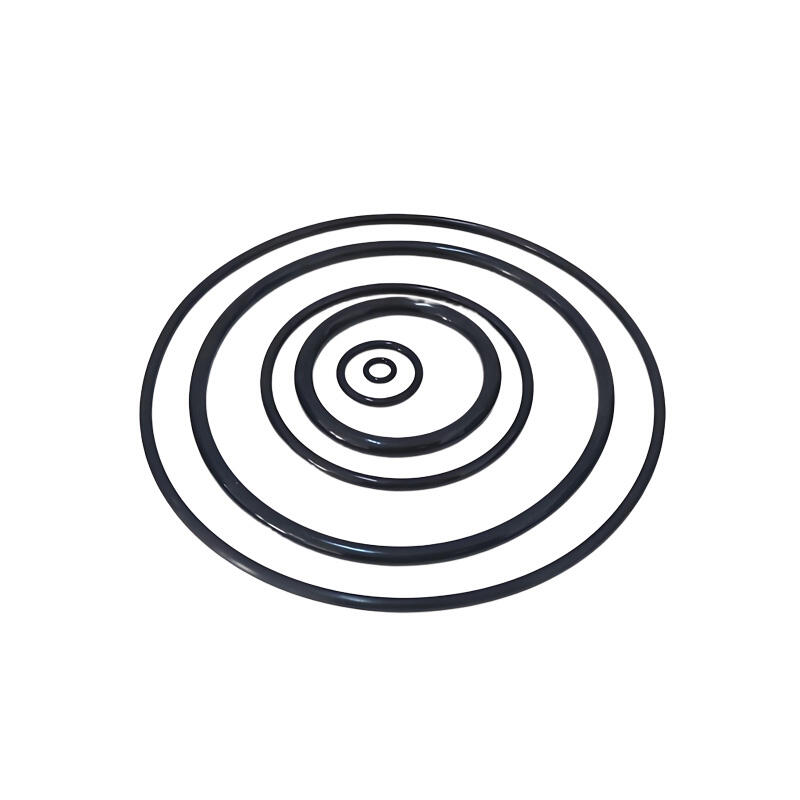

v ring seals

V ring seals, also known as V rings or V seals, are versatile rotary shaft sealing solutions that provide excellent protection against contaminants and fluid leakage. These dynamic sealing elements are designed with a distinctive V-shaped cross-section that creates an effective barrier between the rotating shaft and its housing. The unique design allows the seal to maintain consistent contact pressure against both the shaft and housing surfaces, ensuring reliable sealing performance even under varying operating conditions. The flexible elastomeric material used in V ring seals enables them to accommodate slight shaft misalignment and eccentricity while maintaining their sealing integrity. These seals are particularly valued in industrial applications for their self-adjusting capabilities and ability to operate in both oil and dry-running conditions. The installation process is straightforward, requiring no special tools or housing modifications, making them a cost-effective sealing solution. V ring seals excel in protecting bearings and other critical components from external contamination while effectively retaining lubricants within the system. Their robust construction and durability make them suitable for a wide range of applications, from heavy industrial machinery to automotive components.