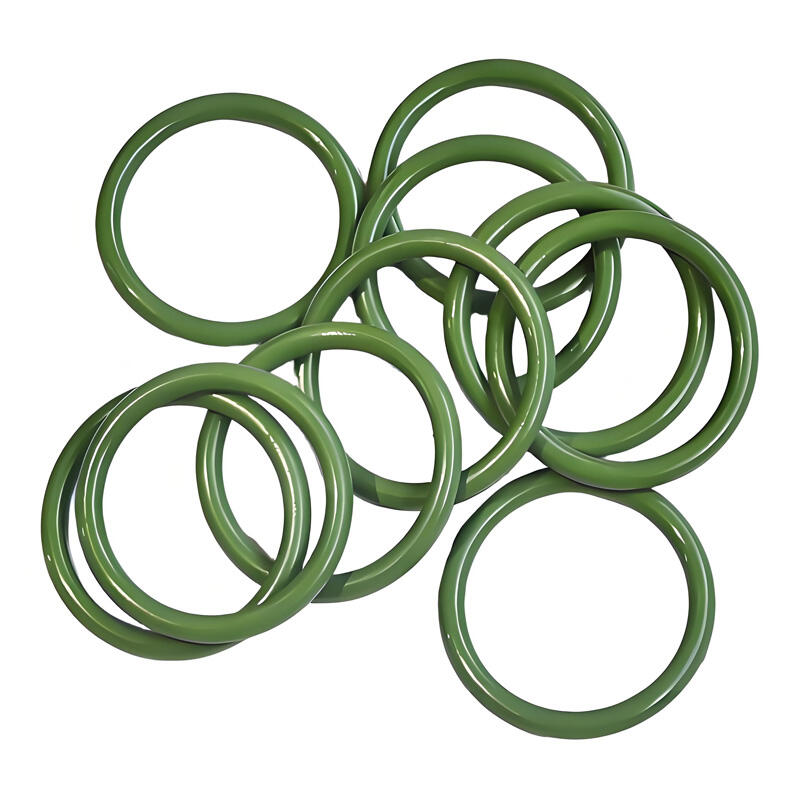

metric oil seals

Metric oil seals represent a crucial component in modern mechanical systems, serving as essential barriers that prevent lubricant leakage while keeping contaminants out of critical machinery parts. These precision-engineered sealing solutions are specifically designed to meet international metric standards, ensuring universal compatibility and reliable performance across various applications. The seals typically consist of a robust elastomer material bonded to a metal case, creating a dynamic sealing lip that maintains constant contact with the shaft surface. This design enables them to operate effectively under diverse conditions, including high-speed rotations, temperature fluctuations, and exposure to various chemicals. The metric standardization allows for precise fitting in equipment manufactured worldwide, making them particularly valuable in global industrial applications. These seals excel in both static and dynamic sealing scenarios, providing exceptional protection for bearings, gearboxes, motors, and other rotating equipment. Their specialized design incorporates features such as garter springs for maintained radial force and precise lip geometry for optimal sealing performance. The materials used in their construction are carefully selected to resist wear, aging, and chemical degradation, ensuring extended service life and reliable operation in demanding industrial environments.