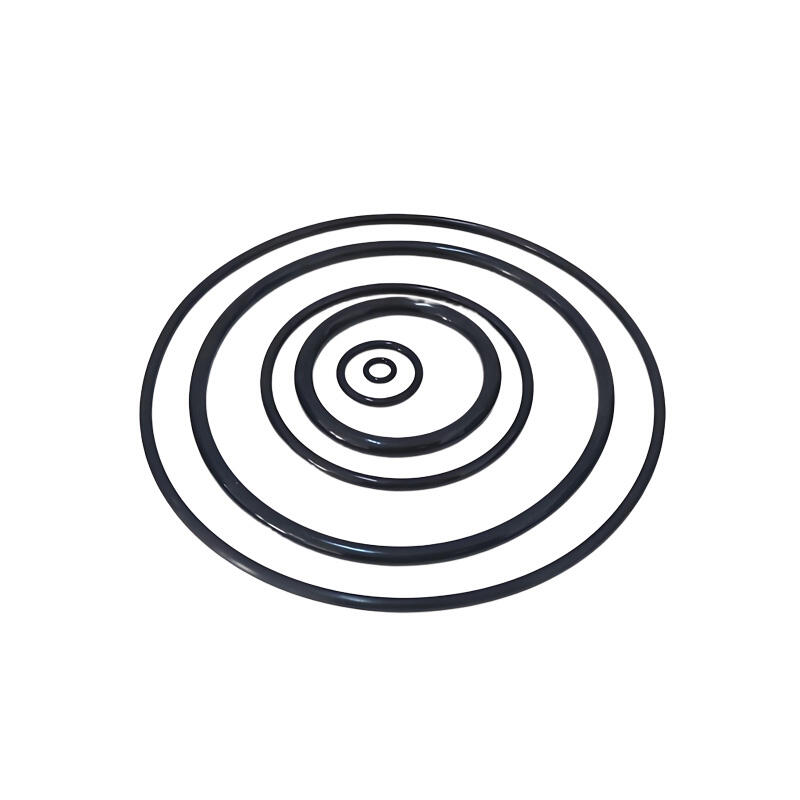

custom o rings

Custom O rings represent a crucial component in modern engineering and manufacturing, offering tailored sealing solutions for diverse industrial applications. These precision-engineered elastomeric seals are designed and manufactured to exact specifications, ensuring optimal performance in specific operating conditions. Custom O rings can be produced using various materials, including nitrile, silicone, EPDM, and fluorocarbon, each selected based on the particular requirements of temperature resistance, chemical compatibility, and pressure tolerance. The manufacturing process involves sophisticated molding techniques that ensure consistent quality and precise dimensions, with options for custom sizes, cross-sections, and material compounds. These specialized seals excel in preventing leakage of gases, fluids, and other substances in dynamic and static applications, making them indispensable in industries ranging from aerospace and automotive to medical devices and heavy machinery. The ability to customize parameters such as inner diameter, cross-section, material hardness, and surface finish allows engineers to optimize sealing performance for specific operating environments, ensuring maximum efficiency and reliability in critical applications.