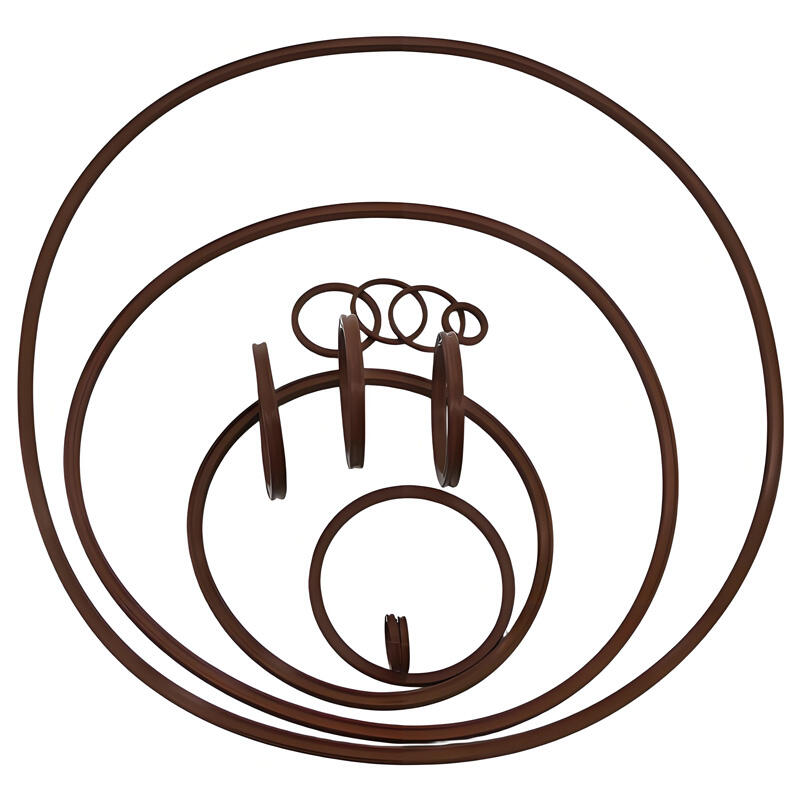

cassette oil seal

A cassette oil seal represents a sophisticated sealing solution that combines multiple components into a single, unified assembly. This advanced sealing device integrates several protective elements, including primary and secondary seals, metal cases, and auxiliary features, all working in harmony to provide superior protection against contamination and fluid leakage. The seal's design incorporates both axial and radial sealing lips, ensuring comprehensive protection in multiple directions. The primary function of a cassette oil seal is to maintain lubricant within mechanical systems while preventing external contaminants from entering. What sets it apart is its pre-assembled nature, which significantly reduces installation errors and enhances overall reliability. These seals are extensively used in heavy-duty applications, particularly in the automotive and industrial sectors, where they protect bearings and other crucial components in wheel hubs, axles, and industrial machinery. The technological advancement in cassette oil seals includes specialized lip designs, optimized contact pressure distribution, and carefully selected materials that contribute to extended service life and improved performance under demanding conditions.