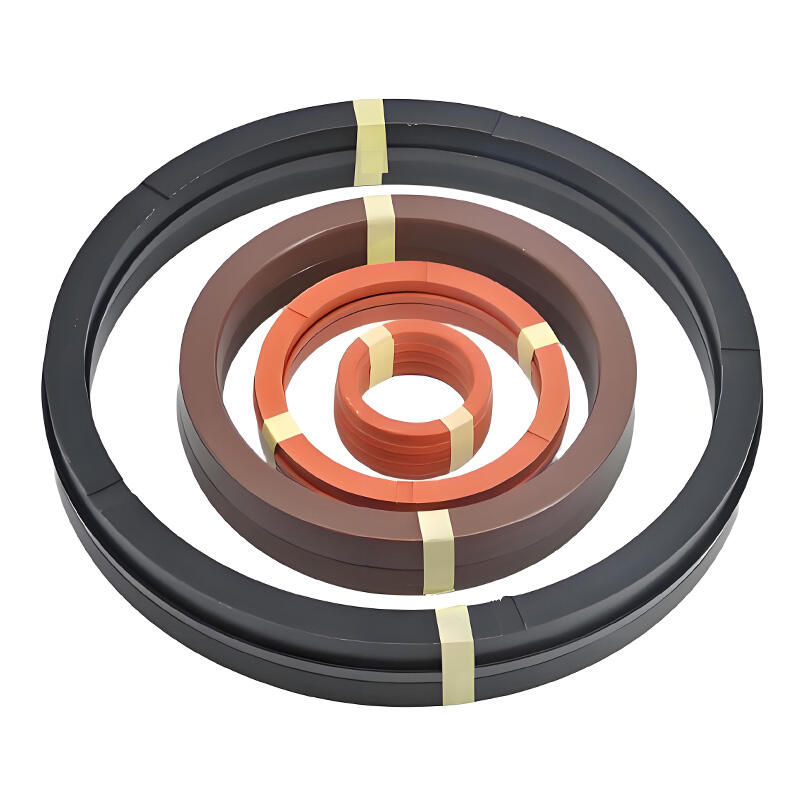

hub oil seal

A hub oil seal is a critical mechanical component designed to prevent oil leakage and protect against contaminant ingress in wheel hub assemblies. This precision-engineered seal creates a reliable barrier between the hub's internal components and external environment, ensuring optimal performance and longevity of the wheel bearing system. The seal consists of multiple layers, typically featuring a durable rubber or synthetic elastomer lip that maintains constant contact with the rotating shaft, while a metal case provides structural support and proper fitting. Advanced hub oil seals incorporate innovative design elements such as multiple sealing lips, specialized surface treatments, and optimized lip geometries to enhance sealing effectiveness. These seals operate effectively across a wide temperature range and can withstand various operating conditions, from everyday commuting to heavy-duty industrial applications. The hub oil seal's design also accounts for proper lubricant retention, which is essential for maintaining the wheel bearing's health and preventing premature wear. Modern manufacturing techniques ensure precise dimensional accuracy and material consistency, resulting in reliable sealing performance throughout the component's service life.