o ring type

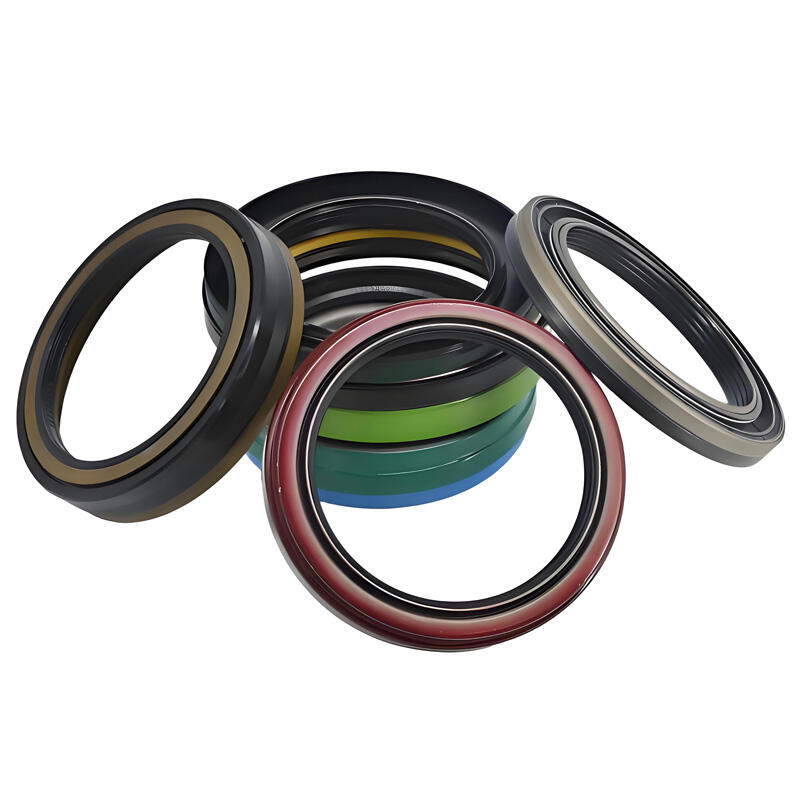

O ring type seals represent a fundamental component in modern engineering and manufacturing, serving as crucial sealing elements across numerous industrial applications. These circular-shaped elastic components, typically manufactured from elastomeric materials, create an effective barrier between two or more mating surfaces to prevent leakage of fluids or gases. The design principle relies on the compression of the O ring within a groove or gland, creating a seal that becomes more effective as pressure increases. O ring types vary in size, material composition, and cross-sectional geometry to suit different operating conditions. The most common materials include nitrile (NBR), fluorocarbon (FKM), and silicone, each offering specific advantages in terms of temperature resistance, chemical compatibility, and durability. These seals can withstand extreme temperatures ranging from -60°C to +300°C depending on the material selection. The versatility of O ring types extends to their application in static, dynamic, and reciprocating sealing situations, making them indispensable in hydraulic systems, pneumatic equipment, automotive applications, and aerospace engineering. Their simple yet effective design allows for easy installation and maintenance, while their reliability and cost-effectiveness have made them the preferred choice for sealing solutions across industries.