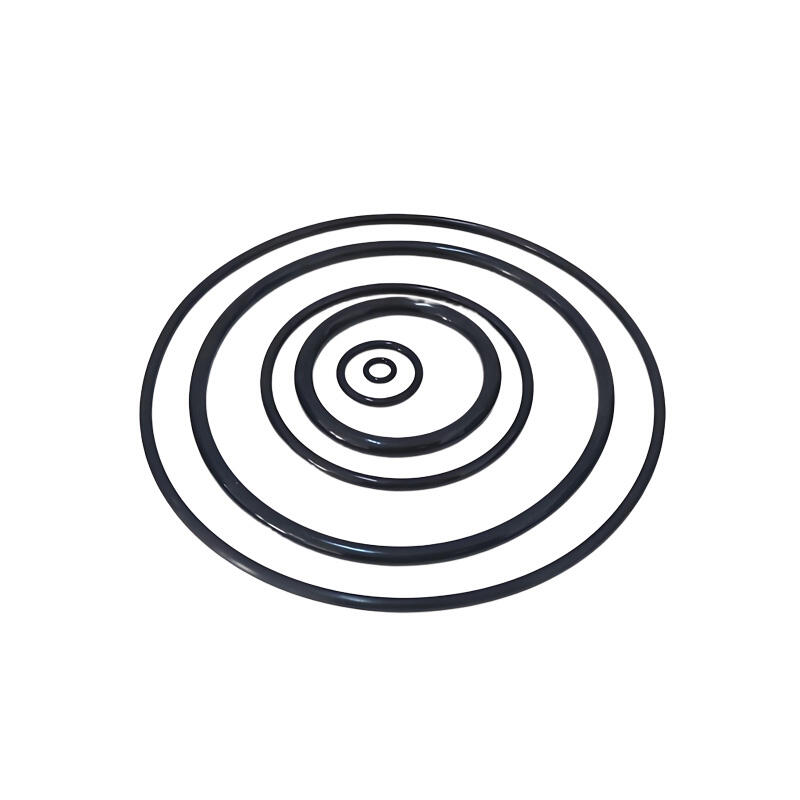

nitrile o rings

Nitrile O rings are essential sealing components manufactured from nitrile butadiene rubber (NBR), offering exceptional resistance to oils, fuels, and various industrial chemicals. These versatile sealing solutions maintain their integrity across a temperature range of -30°C to +120°C, making them ideal for diverse industrial applications. The rings feature a unique molecular structure that provides excellent compression set characteristics and outstanding resistance to wear and tear. Their remarkable elasticity ensures consistent sealing performance under varying pressure conditions, while their cost-effective nature makes them a preferred choice in numerous industrial sectors. The manufacturing process involves precision molding techniques that guarantee uniform density and dimensional accuracy, crucial for maintaining reliable sealing performance. These O rings excel in both static and dynamic applications, offering superior resistance to petroleum-based oils, fuels, and hydraulic fluids. Their robust construction ensures minimal degradation when exposed to harsh environmental conditions, contributing to extended service life and reduced maintenance requirements. The versatility of nitrile O rings makes them indispensable in automotive systems, hydraulic equipment, pneumatic tools, and various industrial machinery where reliable sealing is paramount.