Introduction to Hydraulic Oil Seals

The Critical Role of Hydraulic Oil Seals in Machinery

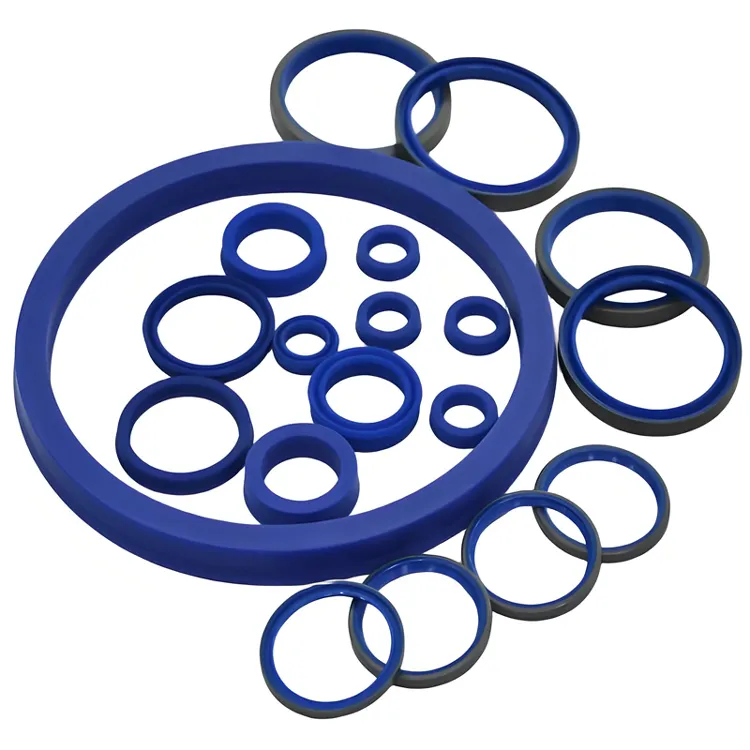

Hydraulic oil seals play a pivotal role in maintaining the operational efficiency of hydraulic systems by effectively containing hydraulic fluids under high pressure. They are indispensable components that prevent fluid leakage, which can lead to severe system failures, environmental hazards, and high financial costs. By ensuring that hydraulic fluids remain contained within the system, these seals prevent contamination from dirt and debris, which could potentially compromise the performance and longevity of machinery. Thus, hydraulic oil seals are critical in safeguarding the equipment and maintaining machinery efficiency.

Why Fluid Leakage Prevention Matters for Industrial Operations

Preventing fluid leakage in industrial operations is essential, primarily because fluid loss directly increases operating costs and diminishes system performance. Fluid leakage prevention not only conserves valuable resources but also supports environmental compliance by minimizing spills and reducing waste. By adhering to stringent leakage prevention standards, companies can enhance machinery reliability, ensure smoother operations, and reduce downtime. Consequently, effective fluid leakage prevention is pivotal for achieving cost management and sustainability in industrial settings, thereby securing a company's economic and environmental objectives.

How Hydraulic Oil Seals Prevent Fluid Leakage

Mechanism of Sealing: Creating a Reliable Barrier

Hydraulic oil seals function as a vital barrier that separates the hydraulic fluid from potential contaminants. Designed with precise lip geometry, these seals adjust to varying operational conditions, ensuring a tight seal. This not only prevents leakage but also limits wear and tear on machinery components by effectively managing hydraulic dynamics. In essence, the sealing mechanism secures the integrity of the system, enhancing operational reliability and longevity.

Types of Hydraulic Seals (Static vs. Dynamic)

Understanding the differences between static and dynamic seals is crucial for optimal technology Application. Static seals work on non-moving surfaces, ensuring that no fluid escapes at these junctures. On the other hand, dynamic seals are crafted for components in motion, adapting to movements without losing their sealing efficiency. Selecting the appropriate type is essential for maximizing system performance and preventing fluid leaks under various operational conditions.

Material Compatibility and Pressure Resistance

The performance of hydraulic oil seals is greatly influenced by the materials used in their construction. Choosing materials that are chemically compatible with the specific hydraulic fluids ensures longevity and functionality. High-quality seals offer superior pressure resistance, maintaining their sealing capacity even under extreme conditions, subsequently reducing the frequency of maintenance and repair. This not only prolongs the life of the machinery but also helps in avoiding unexpected downtimes.

Key Factors in Leak Prevention and Efficiency

Surface Finish and Seal Contact Dynamics

The surface finish of components is pivotal for effective hydraulic seal performance. A smoother surface ensures better contact between the seal and the adjoining component, significantly reducing the chances of fluid leakage. According to experts, improvements in surface roughness can enhance seal performance by maintaining consistent contact, thereby supporting the seal's function effectively over time. Achieving the correct contact dynamics is fundamental to ensuring that hydraulic seals retain their shape without loss of integrity throughout their operational lifecycle.

Temperature and Pressure Management

Managing temperature and pressure within hydraulic systems is crucial to prevent oil leaks and prolong seal life. For instance, fluctuations in temperature can alter the flexibility of seals, weakening them over time and leading to leaks. By maintaining stable temperature and pressure levels, hydraulic systems can achieve greater efficiency and reliability. Optimal temperature and pressure management not only safeguards the seals but also ensures the overall performance and longevity of the hydraulic system, minimizing the risk of equipment downtime.

Contamination Control to Maintain Seal Integrity

Contaminants pose a significant threat to the integrity of hydraulic seals, making control measures indispensable. Effective contamination control involves implementing advanced filtration systems to prevent debris and particulates from compromising seals. Additionally, regular maintenance and thorough inspections are critical to catch signs of contamination early, before they precipitate into larger issues. Maintaining a clean hydraulic system through these means helps ensure that seals remain intact and functional, thereby preventing fluid leaks and maintaining operational reliability.

Performance Benefits of Effective Hydraulic Seals

Enhancing Hydraulic System Pressure Stability

Effective hydraulic oil seals are paramount for maintaining pressure stability within a hydraulic system. By preventing leaks, they ensure that consistent pressure levels are sustained, which is crucial for the system's efficient operation. Without stable pressure, there is a heightened risk of system overloads that can lead to operational failures. Additionally, improved seal function enhances the system's responsiveness, contributing to overall operational efficiency. This underlines the importance of selecting high-quality hydraulic seals to support robust hydraulic system performance.

Reducing Energy Loss and Improving Efficiency

Minimizing leakage rates through optimal sealing solutions plays a significant role in improving energy efficiency. When leaks are reduced, hydraulic systems require less energy to maintain operational pressure, which not only promotes eco-friendly practices but also reduces operational energy costs. This efficiency leads to significant savings, thereby boosting a company’s profitability. By integrating superior hydraulic sealing technologies, businesses can achieve a noteworthy reduction in energy loss, resulting in a sustainable and cost-effective operation.

Extending Equipment Lifespan Through Wear Reduction

The use of effective hydraulic oil seals crucially reduces wear and tear on machinery components by preventing excessive hydraulic fluid exposure. Durable seals decrease the frequency of replacements and repairs, leading to considerable cost savings. Furthermore, investing in high-quality hydraulic seals not only prolongs equipment life but also ensures continuous operation and reliability of machinery. This approach is vital for organizations aiming to safeguard their investments and maintain high-performance levels in their operations.

Conclusion: Recap of the Importance of Hydraulic Oil Seals in Maintaining System Performance and Reliability

Hydraulic oil seals are crucial in maintaining the performance and reliability of hydraulic systems. By preventing leaks, these seals ensure consistent pressure stabilization and enhance overall system efficiency. Furthermore, effective seals contribute to reducing energy losses and extend equipment lifespan, highlighting their role in promoting operational excellence and reliability.

FAQ

What are hydraulic oil seals?

Hydraulic oil seals are components used in machinery to effectively contain hydraulic fluids under high pressure, preventing leaks and contamination.

Why is fluid leakage prevention important?

Fluid leakage prevention is crucial because it reduces operating costs, supports environmental compliance, and enhances machinery reliability.

What materials are used in hydraulic oil seals?

The materials used vary but must be compatible with hydraulic fluids; they need to offer good pressure resistance and durability.

How do hydraulic oil seals enhance system efficiency?

By ensuring stable pressure levels and preventing leaks, hydraulic oil seals enhance system efficiency and reduce energy loss.

What is the difference between static and dynamic hydraulic seals?

Static seals are for non-moving surfaces, whereas dynamic seals adapt to motion, ensuring fluid containment in both cases.