Overview of Wind Turbines in Renewable Energy

Wind turbines are essential in harnessing wind energy, which is a clean and sustainable power source. They play a significant role in reducing carbon emissions, thus helping in the fight against climate change. As these turbines capture the kinetic energy from the wind and convert it into electricity, they provide a renewable alternative to fossil fuels, reducing the environmental footprint of power generation.

With the increasing global energy demands, integrating wind energy into the energy mix has never been more crucial. This integration supports energy security and sustainability goals, addressing the world's growing need for clean energy solutions. According to the Global Wind Report 2022, a projected 557 GW of new capacity is expected to be added in the next five years, underscoring the accelerating adoption of wind power worldwide.

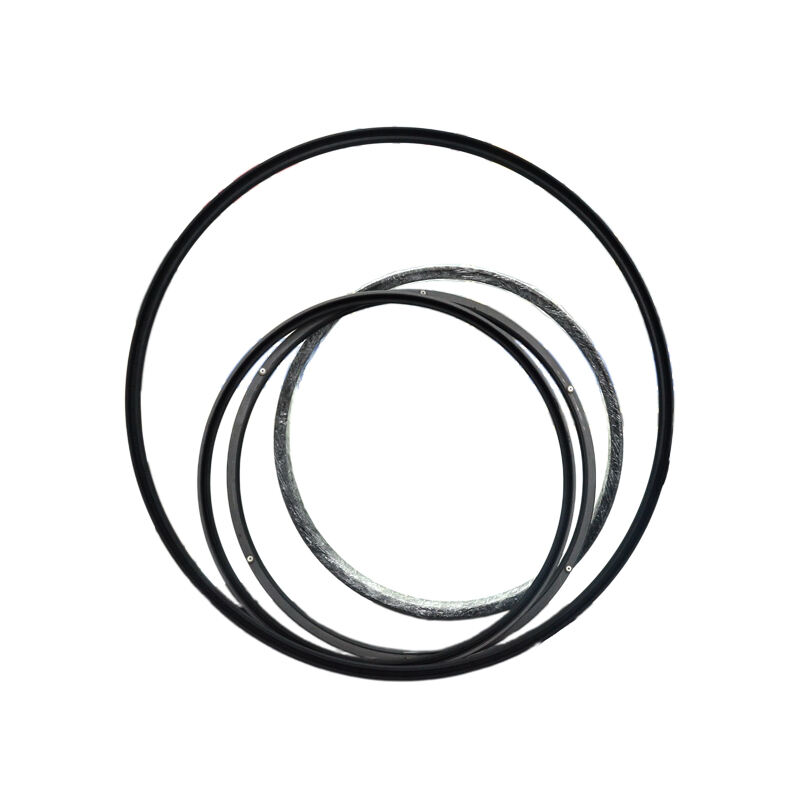

Seals are critical in ensuring the operational longevity and efficiency of wind turbines. They help prevent potential failures and maintenance issues, which could lead to costly downtimes. The proper functioning of seals in components like the hydraulic pitch cylinder ensures that the wind turbines operate smoothly, optimizing energy capture and enhancing overall system reliability. Keywords like "Wind Turbine Seals" highlight the pivotal role of these components in maintaining turbine efficiency.

Role of Seals in Wind Turbines

Protecting Components from Moisture, Dust, and Contaminants

Seals are fundamental in safeguarding wind turbine components from environmental hazards like moisture and dust. Their significance lies in their ability to prevent premature wear and operational failures. Research indicates that effective sealing can reduce maintenance downtime by up to 30%, pivotal for enhancing the reliability of wind turbines. High-quality seals also act as barriers against contaminants that could otherwise compromise the performance of crucial components like gearbox oils and lubricants [source]. By ensuring these elements remain uncontaminated, seals help maintain optimal turbine function over long periods, significantly contributing to the efficiency and longevity of the machinery.

Impact of Wind Turbine Seals on Efficiency

Preventing Energy Loss and Enhancing Reliability

Effective seals play a crucial role in minimizing energy loss within wind turbines by preserving the integrity of various systems. This ensures that power generation remains consistent and reliable. According to industry analysts, well-sealed turbines can boost overall system efficiency by approximately 2-5%. This enhancement is particularly significant in large-scale wind farms, where even minor efficiency gains contribute substantially to energy production. Moreover, seals also help reduce wear on moving parts, thereby extending the operational life of the turbines. Research from industry experts highlights that the right seals can enhance the reliability of turbines by mitigating wear and tear on these components. In essence, these seals not only prevent energy loss but also enhance the overall robustness and efficiency of wind energy systems. Such features underscore the importance of high-quality wind turbine seals in the pursuit of optimal energy production and sustainability.

Types of Seals Used in Wind Turbines

Shaft Seals and Their Functions

Shaft seals are pivotal in wind turbines for preventing the escape of lubricants and the ingress of foreign particles, ensuring the smooth operation of turbine drivetrains. These seals are essential in maintaining the integrity and efficiency of the drivetrain by blocking contaminants that could otherwise lead to increased friction and wear. To withstand the varying loads and temperatures endured by wind turbines, materials such as polytetrafluoroethylene (PTFE) and rubber are commonly used due to their resilience and durability. Regular inspections of shaft seals are crucial to detect early signs of wear and tear, helping to prevent costly repairs or replacements in the future. This proactive approach can significantly extend the lifespan of the seal and enhance overall turbine performance.

Rotor Seals and Their Roles

Rotor seals are integral to the efficient operation of wind turbines, as they secure the attachment of blades to the rotor hub, thus maintaining aerodynamics and optimizing energy capture. Given the dynamic stress caused by wind forces, these seals must be made from materials capable of withstanding dynamic loads while effectively sealing to prevent air leakage. Recent advancements in seal design, such as the use of composite materials, have significantly improved the performance and longevity of rotor seals. These innovative materials offer enhanced strength and flexibility, ensuring that rotor seals can sustain substantial forces and environmental conditions while reducing maintenance needs over time. By ensuring the reliable attachment and functioning of turbine blades, rotor seals play a crucial role in maximizing the efficiency and energy output of wind turbines.

Maximizing Wind Turbine Efficiency with Seals

The Critical Role of Seals in Renewable Energy

Seals are a crucial component in enhancing the efficiency of renewable energy systems, particularly wind turbines. They have a direct impact on the operational costs and performance of these devices. As wind turbines become more complex and larger in scale, the need for advanced sealing technology becomes vital. The development of seals that can withstand high dynamic loads and environmental extremes is essential to achieving greater performance metrics. Innovations in sealing solutions help optimize efficiency by reducing wear and friction, which in turn prolongs service life and minimizes maintenance costs. This advancement is necessary for wind energy systems to compete effectively with traditional energy sources, supporting the global transition towards sustainability. As the industry evolves, ongoing research and development in seal materials and designs are paving the way for even more efficient and reliable wind energy systems.

FAQ

Q: Why are seals important in wind turbines?

A: Seals are crucial for maintaining the efficiency and operational longevity of wind turbines by protecting components from environmental hazards and preventing energy loss.

Q: How do seals enhance the reliability of wind turbines?

A: High-quality seals minimize energy loss, reduce wear on components, and act as barriers against contaminants, enhancing the reliability and efficiency of wind turbines.

Q: What types of materials are used for shaft seals in wind turbines?

A: Materials such as polytetrafluoroethylene (PTFE) and rubber are commonly used for shaft seals due to their resilience and ability to withstand varying loads and temperatures.

Q: How do rotor seals contribute to wind turbine efficiency?

A: Rotor seals secure the attachment of blades to the rotor hub, maintaining aerodynamics and optimizing energy capture, thus playing a crucial role in maximizing turbine efficiency.